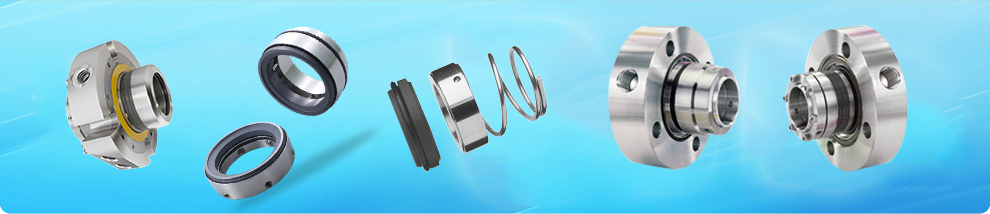

Double Mechanical Seal

Double Mechanical Seal

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

Double mechanical seal are offering the Two arrangements:-

Back to Back

Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

Face to Face

The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Double mechanical seals are commonly used in the following circumstances:

- If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

- When aggressive media are used at high pressures or temperatures

- For many polymerizing, sticky media