Mechanical Seal Repair, Re-Conditioning & Lapping

Mechanical Seal repair is available on all seal manufacturers, A failure analysis is performed on every seal to determine why the seal failed. We will always make any necessary suggestions that will lead to increased seal life during or before mechanical seal repair.

All Seal Components are completely cleaned, measured, pressure tested and inspected by the engineering department to determine which parts can be re-used or require replacement.

Seal faces are lapped with industry standards on lapping machine within our controlled lapping room.Machine lapping is the manufacture method of lapping Mechanical Seal Faces. Seal care Lapping Systems are used in both manufacturing and reconditioning processes. The following techniques are applicable to Bench Mounted and Free Standing Machines, as well as Seal care Hand Lapping Systems.

Re-Conditioning Procedure:

Chemical Cleaning and Ultrasonic Cleaning of all Hardwares, Stationary Seal Surface Grinding, Lapping and New Gasket, Rotary Seal Face change V-Rings and Back-up rings. Seal Face Lapping to one light band.

We identify and recondition damages in cartridge seals and restore the seal back to working condition.

Seal Care offer one of the best mechanical seal restoration services in the Singapore.

- All wearing parts replaced.

- All faces lapped to within 2 light bands 0.0001 microns.

- All cartridge & agitator seals pressure tested to manufacturers specifications.

- All mechanical seals serviced & repaired.

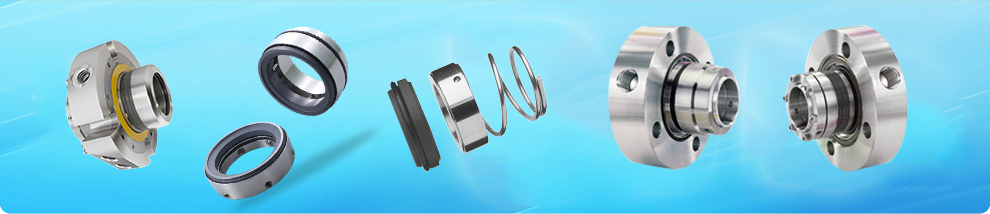

Below is a typical example of a seal repair pictures we done for our customers.