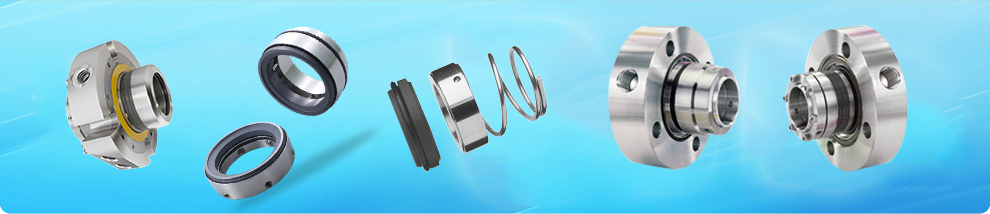

3710 Cartridge Split Seal :

When water is frozen , it will expand in volume. When this frozen water is inside a pipe, pipe can burst and the escaping water can cause a serious damage. To prevent frozen pipes, the break is not from the extreme expansion of the water. When the ice completely blocks the flow of water and when the increase in pressure of water flow this blockage it will cause a pipe bursting. When the pipes have a smaller diameter the blockage is more likely to occur. Both utilities and homeowners need to take special precautions to prevent pipe bursting.

When water is frozen , it will expand in volume. When this frozen water is inside a pipe, pipe can burst and the escaping water can cause a serious damage. To prevent frozen pipes, the break is not from the extreme expansion of the water. When the ice completely blocks the flow of water and when the increase in pressure of water flow this blockage it will cause a pipe bursting. When the pipes have a smaller diameter the blockage is more likely to occur. Both utilities and homeowners need to take special precautions to prevent pipe bursting.

The Type 3710 Cartridge Split Seal is the latest innovation in the evolution of split seal designs. It utilizes John Crane's advanced split seal technology to meet today's environmental guidelines and future regulations. The unique, easy-to-install design readily adapts to horizontal and vertical pumps, mixers, and agitators. The Type 3710 is ideal for applications where reliability and minimal downtime are essential.

With over 30 years of split seal experience, from sophisticated marine propeller shaft seals to thousands of industrial pump and mixer applications, John Crane has established itself as the worldwide expert in split seal technology.

Fast & Easy Installation:

The Type 3710 eliminates the need to dismantle any piece of equipment, large or small. Its fully split design can be installed in less than 30 minutes, either on the packing sleeve or directly to the shaft. The cartridge design eliminates any measuring or centering of the seal, making assembly easy, while ensuring long seal life.Available to fit metric and inch sizes, there is a Type 3710 to fit most standard equipment.

Application:

The John Crane Type 3710 Cartridge Split Seal is rugged in construction and designed for use in sealing rotating equipment in a variety of process industries such as:

- Pulp & Paper

- Waste/Wastewater

- Refinery

- Petrochem

- Chemical

- Food Processing

Reliable Alternative to Packing:

The Type 3710 split seal will help to reduce maintenance and operating costs by providing a reliable alternative to packing.

Cost-saving advantages over packing include:

- Reduces bearing contamination from the packing leakage,the leading cause of bearing failure.

- Eliminates costly sleeve/shaft replacement due to scoring damage caused by packing.

- Reduces maintenance costs by eliminating time-consuming packing adjustments.

- Energy costs are significantly reduced due to lower frictional horsepower requirements.