Water Pump Mechanical Seal

Water Pump Mechanical Seal

We also supply different types of pumps like Centrifugal Pumps (API610, ISO, DIN, ANSI Standards), Air Operated Diaphragm pump , Screw Pumps, Submersible Pumps, Fire Water Pumps (FM/UL Listed and Non FM/UL Listed), Positive Displacement Pumps (API676, API674, API675) for various applications.

Submersible pump:

These pumps are made using premium quality components procured from reliable sources of the industry. The offered pumps prevent water from building up in the basement, which prevent bacteria from multiplying and humidity from forming. These sump pumps are installed in-ground and are designed to work underwater. These Submersible Sump Pumps are available in different specifications as per the needs of the clients.

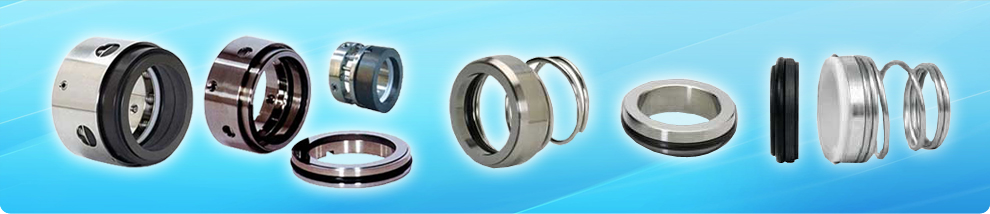

GLR mechanical seal

We put forth for our clients an extensive array of GLR Mechanical Seals. These seals are renowned among the patrons for their accurate results .

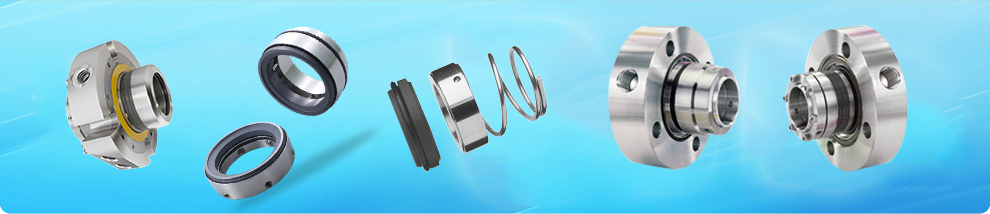

GMM Mechanical Seal:

We are counted among the prominent organizations engaged in offering a wide array of GMM Mechanical Seals. Our seals are extensively used for preventing oil leakage in various machines. These products are highly reliable owing to the use of optimum quality material in their manufacturing.

Self Priming Pump:

We have been widely known in the market for our ability to manufacture, supply and export a genuine quality range of Self Priming Pumps. These pumps are precisely engineered by a team of experts, which has immense expertise and experience in this domain. The range of pumps offered by us is designed and made in accordance with the industrial requirements.

Advantages of Water Pump Mehanical Seal:-

The advantages of this seal type are the ability to handle high and low temperature applications (metal bellows), and that it does not require a rotating secondary seal, which means it is not prone to secondary seal hang-up or shaft/sleeve fretting. Elastomeric bellows seals are commonly used for water applications.The advantages are that this seal configuration eliminates the requirement for seal setting measurements at installation. Cartridge seals lower maintenance costs and reduce seal setting errors.

The disadvantages are that thin bellows cross sections must be upgraded for use in corrosive environments, plus the higher cost of metal bellows seals.

Cartridge seals have the mechanical seal pre-mounted on a sleeve (including the gland). They fit directly over the shaft or shaft sleeve, and are available in single, double, and tandem configurations. Best of class pump users give strong consideration to the use of cartridge seals.